Cotton is a soft, fluffy staple fiber that

grows in a boll, or protective capsule, around the seeds of cotton plants

of the genus Gossypium. The fiber is almost pure cellulose. Under

natural condition, the cotton balls will tend to increase the dispersion of the

seeds.

The

fiber is most often spun into yarn or thread and used to make a soft,

breathable textile. The use of cotton for fabric is known to date to

prehistoric times; fragments of cotton fabric dated from 5000 BC have been

excavated in Mexico and the Indus Valley Civilization (modern day Pakistan).

Although cultivated since antiquity, it was the invention of the cotton

gin that so lowered the cost of production that led to its widespread use,

and it is the most widely used natural fiber cloth in clothing today.

Current

estimates for world production are about 25 million tonnes annually,

accounting for 2.5% of the world's arable land. China is the world's largest

producer of cotton, but most of this is used domestically. The United States

has been the largest exporter for many years.

Types of Cotton Fibre:

There

are four commercially-grown species of cotton, all domesticated in antiquity:

Gossypium hirsutum – upland cotton,

native to Central America, Mexico, the Caribbean and southern Florida, (90% of

world production)

Gossypium barbadense – known as

extra-long staple cotton, native to tropical South America (8% of world

production)

Gossypium arboreum – tree cotton,

native to India and Pakistan (less than 44%)

Gossypium herbaceum – Levant cotton,

native to southern Africa and the Arabian Peninsula (less than 2%)

Cotton Consumption & Production in

million Tons in year 2002:

The

graph bellow shows Production and consumption of leading cotton producing

countries in Millions of tones in year 2002.

COUNTRIES

|

PRODUCTION

|

CONSUMPTION

|

US

|

3.8

|

1.7

|

India

|

2.5

|

3

|

Pakistan

|

1.8

|

1.9

|

Turkey

|

0.9

|

1.4

|

Brazil

|

0.7

|

0.9

|

Indonesia

|

0.4

|

0.6

|

China

|

4.8

|

5.9

|

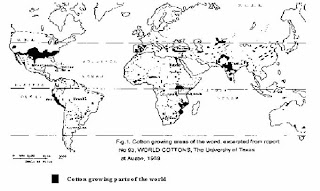

Today, cotton is grown in more than 80 countries worldwide. The Distribution of cotton is shown in the bellow Map:

Characteristics of Cotton:

Cotton,

as a natural cellulosic fiber, has a lot of characteristics, such as;

a)

Comfortable

Soft hand

b)

Good

absorbency

c)

Color

retention

d)

Prints

well

e)

Machine-washable

f) Dry-cleanable

g) Good strength

h) Drapes well

i) Easy to handle and sew

End Uses of Cotton:

End Uses of Cotton:

Apparel

- Wide range of wearing apparel: blouses, shirts, dresses, childrenswear,

active wear, separates, swimwear, suits, jackets, skirts, pants, sweaters,

hosiery, neckwear.

Home

Fashion - curtains, draperies, bedspreads, comforters, throws, sheets, towels,

table cloths, table mats, napkins.

Structure & Properties of Cotton Fibre:

Fibre Structure &

Formation:

The

botanical name of American Upland cotton is Gossypium Hirsutum and

has been developed from cottons of Central America. Upland varieties

represent approximately 97% of U.S. production.

Each cotton fiber is composed of concentric layers. The cuticle layer on the fiber itself is separable from the fiber and consists of wax and pectin materials. The primary wall, the most peripheral layer of the fiber, is composed of cellulosic crystalline fibrils. The secondary wall of the fiber consists of three distinct layers. All three layers of the secondary wall include closely packed parallel fibrils with spiral winding of 25-35o and represent the majority of cellulose within the fiber. The innermost part of cotton fiber- the lumen- is composed of the remains of the cell contents. Before boll opening, the lumen is filled with liquid containing the cell nucleus and protoplasm. The twists and convolutions of the dried fiber are due to the removal of this liquid. The cross section of the fiber is bean-shaped, swelling almost round when moisture absorption takes place.

The

overall contents are broken down into the following components.

Raw Cotton Components:

80-90%

|

Cellulose

|

6-8%

|

Water

|

0.5 -

1%

|

Waxes

and fats

|

0 -

1.5%

|

Proteins

|

4 -

6%

|

Hemicelluloses

and pectin’s

|

1 -

1.8%

|

Ash

|

During

scouring (treatment of the fiber with caustic soda), natural waxes and fats in

the fiber are saponified and pectin’s and other non-cellulose materials are

released, so that the impurities can be removed by just rinsing away. After

scouring, a bleaching solution (consisting of a stabilized oxidizing agent)

interacts with the fiber and the natural color is removed. Bleaching takes

place at elevated temperature for a fixed period of time. Mercerization is

another process of improving sorption properties of cotton. Cotton fiber is

immersed into 18- 25% solution of sodium hydroxide often under tension. The

fiber obtains better luster and sorption during mercerization.

After

scouring and bleaching, the fiber is 99% cellulose. Cellulose is a polymer consisting

of anhydroglucose units connected with 1,4 oxygen bridges in the beta position.

The hydroxyl groups on the cellulose units enable hydrogen bonding between two

adjacent polymer chains. The degree of polymerization of cotton is 9,000-15,000.

Cellulose shows approximately 66% crystallinity, which can be determined by

X-ray diffraction, infrared spectroscopy and density methods.

Each

crystal unit consists of five chains of anhydroglucose units, parallel to the

fibril axis. One chain is located at each of the corners of the cell and one

runs through the center of the cell. The dimensions of the cell are a =

0.835nm, b = 1.03 nm and c = 0.79 nm. The angle between ab and BC planes is 84º

for normal cellulose, i.e., Cellulose I .

Repeat Unit of Cellulose:

The

current consensus regarding cellulose crystallinity (X-ray diffraction) is that

fibers are essentially 100% crystalline and that very small crystalline units

imperfectly packed together cause the observed disorder.

The

density method used to determine cellulose crystallinity is based on the

density gradient column, where two solvents of different densities are

partially mixed. Degree of Crystallinity is, then, determined from the density

of the sample, while densities of crystalline and amorphous cellulose forms are

known (1.505 and 1.556 respectively). Orientation of untreated cotton fiber is

poor because the crystallites are contained in the micro fibrils of the

secondary wall, oriented in the steep spiral (25-30o) to the fiber axis.

Physical Properties of Cotton:

Fibre

Length:

Fiber

length is described as "the average length of the longer one-half of the

fibers (upper half mean length)" This measure is taken by scanning a

"beard " of parallel fibers through a sensing region. The beard is

formed from the fibers taken from the sample, clasped in a holding clamp and

combed to align the fibers. Typical lengths of Upland cottons might range from

0.79 to 1.36in.

Cottons

come from the cotton plant; the longer strand types such as Pima or Sea Island produce

the finest types of cotton fabrics.

Leangth

Uniformity:

Length

uniformity or uniformity ratio is determined as " a ratio between the mean

length and the upper half mean length of the fibers and is expressed as a

percentage". Typical comparisons are illustrated below.

LENGTH

UNIFORMITY

|

UNIFORMITY

INDEX [%]

|

Very

High

|

>85

|

High

|

83-85

|

Intermediate

|

80-82

|

Low

|

77-79

|

Very

Low

|

<77

|

Low

uniformity index shows that there might be a high content of short fibers,

which lowers the quality of the future textile product.

Fibre

Strength:

Fiber

strength is measured in grams per denier. It is determined as the force

necessary to break the beard of fibers, clamped in two sets of jaws, (1/8 inch

apart) . Typical tensile levels are illustrated. The breaking strength of

cotton is about 3.0~4.9 g/denier, and the breaking elongation is about 8~10%.

DEGREE

OF STRENGTH

|

FIBER

STRENGTH [g/tex]

|

Very

Strong

|

>31

|

Strong

|

29-30

|

Average

|

26-28

|

Intermediate

|

24-25

|

Weak

|

<23

|

Micronaire:

Micronaire

measurements reflect fiber fineness and maturity. A constant mass (2.34 grams)

of cotton fibers is compressed into a space of known volume and air

permeability measurements of this compressed sample are taken. These, when

converted to appropriate number, denote Micronaire values.

COTTON RANGE

|

MICRONAIRE READING

|

Premium

|

3.7-4.2

|

Base Range

|

4.3-4.9

|

Discount Range

|

>5.0

|

Color

of Cotton

The

color of cotton samples is determined from two parameters: degree of

reflectance (Rd) and yellowness (+b). Degree of reflectance shows the

brightness of the sample and yellowness depicts the degree of cotton

pigmentation. A defined area located in a Nickerson-Hunter cotton colorimeter

diagram represents each color code. The color of the fibers is affected by

climatic conditions, impact of insects and fungi, type of soil, storage

conditions etc. There is five recognized groups of color: white, gray, spotted,

tinged, and yellow stained. As the color of cotton deteriorates, the process

ability of the fibers decreases.

Work at

the University of Tennessee has led to color measurement

using both a spectrometer CIE-based average color measurement and a color uniformity

measurement using image analysis to improve the accuracy and provide additional

measurement for color grading [19]. Later the investigators developed two color

grading systems using expert system and neural networks.

Trash:

A trash

measurement describes the amount of non-lint materials (such as parts of cotton

plant) in the fiber. Trash content is assessed from scanning the cotton sample

surface with a video camera and calculating the percentage of the surface area

occupied by trash particles. The values of trash content should be within the

range from 0 to 1.6%. Trash content is highly correlated to leaf grade of the

sample.

Leaf

Grade:

Leaf

grade is provided visually as the amount of cotton plant particles within the

sample. There are seven leaf grades (#1-#7) and one below grade (#8).

Preparation:

Preparation

is the classer's interpretation of fiber process ability in terms of degree of

roughness or smoothness of ginned cotton.

Extraneous

matter:

Extraneous

matter is all the material in the sample other than fiber and leaf. The classer

either as “light” or “heavy” determines the degree of extraneous matter.

Neps:

A nep

is a small tangled fiber knot often caused by processing. Neps can be measured

by the AFIS nep tester and reported as the total number of neps per 0.5 grams

of the fiber and average size in millimeters. Nep formation reflects the

mechanical processing stage, especially from the point of view of the quality

and condition of the machinery used.

Chemical Properties of Cotton:

Cotton

swells in a high humidity environment, in water and in concentrated solutions

of certain acids, salts and bases. The swelling effect is usually attributed to

the sorption of highly hydrated ions. The moisture regain for cotton is about

7.1~8.5% and the moisture absorption is 7~8%.

Cotton

is attacked by hot dilute or cold concentrated acid solutions. Acid hydrolysis

of cellulose produces hydro-celluloses. Cold weak acids do not affect it. The

fibers show excellent resistance to alkalis. There are a few other solvents

that will dissolve cotton completely. One of them is a copper complex of

cupramonium hydroxide and cupriethylene diamine (Schweitzer's reagent).

Cotton

degradation is usually attributed to oxidation, hydrolysis or both. Oxidation

of cellulose can lead to two types of so-called oxy-cellulose, depending on the

environment, in which the oxidation takes place.

Insert

Formula or Equation: Oxy-Cellulose:

Also,

cotton can degrade by exposure to visible and ultraviolet light, especially in

the presence of high temperatures around 250~397° C [20] and humidity.

Cotton fibers are extremely susceptible to any biological degradation

(microorganisms, fungi etc.)

Optical

Properties of Cotton:

Cotton

fibers show double refraction when observed in polarized light. Even though

various effects can be observed, second order yellow and second order blue is

characteristic colors of cellulosic fibers. [10] A typical birefringence value

as shown in the table of physical properties, is 0.047.

Cotton

Classification:

Cotton

classification is used to determine the quality of the cotton fiber in terms of

grade, length and Micronaire. USDA classification specifically identifies the

characteristics of fiber length, length uniformity, strength, Micronaire,

color, preparation, leaf and extraneous matter. In the past, these qualities

were classified just by hand-and-eye of an experienced classer. Since 1991, all

classification has been carried out with a set of up-to-date instruments,

called "HVI"(High Volume Instrumentation) classification. However,

measuring techniques of other qualities of cotton fiber, such as fiber maturity

and short fiber content, are also being developed.

Cotton

in non-wovwns:

Cotton

is the most important apparel fiber throughout the world. It is a fiber that

was used fairly extensively during the early, developmental period of the

Nonwovens business primarily because the emerging dry-laid producers came from

the textile industry and had an intimate knowledge of cotton and its processing

characteristics [25].It was in the early part of 20th Century that a few cotton

mills in the US wanted to find ways to upgrade the waste cotton fibers into

saleable products. The first method used was bonding the short cotton fibers

(fiber waste) with latex and resin. These products were used mainly as

industrial wipes. After World War II, products like draperies, tablecloths,

napkins and wiping towels were developed. It was realized that woven fabrics

have much better properties than Nonwovens; so, the approach was to claim the

market where superior qualities of woven or knit fabrics were not essential but

where qualities better than those of paper were needed. As the quality requirements

for nonwoven fabrics increased and particularly as the need for white, clean

fabric emerged; the use of raw cotton became unacceptable and was abandoned by

the industry except for a few isolated product areas. Within the last decade,

bleached cotton fiber suitable for processing on conventional nonwoven

equipment has become available and has substantially increased interest in this

fiber. This is particularly true in medical and healthcare applications, wiping

and wiper markets, and some apparel markets. The raw cotton consists of about

96% cellulose and 4% of waxes, pectin, and other pertinacious and plant

material. These minor constituents that must be removed in the scouring and

bleaching process to give the soft, clean, white, absorbent fiber that is

satisfactory for the nonwovens industry after the application of an appropriate

finishing oil. The fiber length of cotton is important, particularly as to its

process ability. Longer staple cotton (0.75 in. to 1.25 in.) is satisfactory

for nonwoven production. The fiber has excellent absorbency and feels

comfortable against the skin. It has fairly good strength both wet and dry, and

has moderate dimensional stability and elastic recovery. But the resilience of

cotton is relatively low, unless it is cross-linked by a chemical treatment. In

nonwoven applications, the purity and absorbency of bleached cotton are

utilized in growing medical and healthcare applications. The spun lace process

usually produces such fabrics. For similar reasons, cotton spun lace fabrics

are well accepted in personal and related wipes, especially in Japan and

the ASIAN region. In a sense, bleached cotton fiber for nonwoven application is

a relatively new fiber. It is a comparatively expensive fiber and available

from only a few sources. Consequently, its use still is restricted to

specialized applications. This situation is likely to change in the future as

the price is further reduced and availability increased.

Fibre Processing:

About

30% of world cotton machines harvest production Australia, Israel and USA are

the only countries where all cottons are picked by machines. Fifteen percent of

world cotton production is ginned on roller gins and almost all rest of cotton

is saw ginned in most countries.Cotton fibers in non-wovens are generally used

in their bleached form. A lot of research and development has taken place for

the efficient production of bleached fibers. The Kier bleaching process

produces most of the bleached cotton fibers. Since cotton of lesser grades is

useful for non-wovens, a conventional cleaning system does not suffice. This

might include a coarse wire carding, called Cotton Master Cleaners, for

cleaning the cotton.

The

conventional bleaching method for cottons meant for non-wovens is a 9 step

process are:

a)

Fiber opening and cleaning

b) Alkali scouring application

c) Alkali reaction stage

d) Rinsing

e) Bleach application

f) Bleach reaction stage

g) Rinsing

h) Finish application

i) Drying

b) Alkali scouring application

c) Alkali reaction stage

d) Rinsing

e) Bleach application

f) Bleach reaction stage

g) Rinsing

h) Finish application

i) Drying

A

continuous textile processing system and method have been disclosed recently

for producing a nonwoven web containing bleached cotton fibers in a single line

system which includes a supply of fibers such as a bale opening device, The

final nonwoven web consisting of bleached cotton fibers may be made into highly

purified and absorbent wipes, pads, and other articles for medical, industrial,

or domestic use.

Finally,

there is opening and bale formation.

Cotton

Incorporated patented a processing line, which promised better

productivity and quality. It consists of:

a)

Fiber opening and Cleaning

b) Formation of web

c) Steam purging and Alkali impregnation onto the sandwiched cotton web between 2 porous conveyors.

b) Formation of web

c) Steam purging and Alkali impregnation onto the sandwiched cotton web between 2 porous conveyors.

d)

After reaction, a pressure squeezing operation.

e) Similar processes for bleaching and then finishing.

e) Similar processes for bleaching and then finishing.

The

recent system for scouring a bleaching of cotton fiber is the Continuous Wet

Finishing Technique' patented by Lawrence Girard and Walter E Meyer and

assigned to Greenville Machinery Corporation. It consists of:

a) Opening and Cleaning

b) Conversion of fibers into a bat, weighing 10-30 ounces/sq. yard, by Needle punching or

Air-lay technique.

c) Scouring

d) Bleaching

e) Finishing

f) Washing

g) Drying

h) Fiber opening

a) Opening and Cleaning

b) Conversion of fibers into a bat, weighing 10-30 ounces/sq. yard, by Needle punching or

Air-lay technique.

c) Scouring

d) Bleaching

e) Finishing

f) Washing

g) Drying

h) Fiber opening

Advantages

of Continuous Finishing Techniques are:

a) Uniformity of scouring and bleaching

b) Uniformity of finish application

c) Shorter time in process for the materials

d) Lower water consumption and less effluent for treatment

e) The ability to provide additional chemical treatments to the cotton.

Cost of Producing Cotton:

The

international cotton advisory committee (ICAC) undertakes a survey of the cost

of the production of cotton every three years based on the data from 31

countries. [16] Several factors are considered, such as land rent, fertilizers,

insect control, irrigation, harvesting and ginning. The cost of seed cotton is

more than $500 in USA to produce one hectare of seed cotton. The net

cost of producing lint from one hectare (the value of seed and land rent were

excluded from the total cost) is highest in Australia (US$1,056)

followed by the USA (US$889), Pakistan (US$814), Zimbabwe (US$426)

and China (US$416). It is most expensive to produce a kilogram of

lint in the USA (US$1.20), Australia (US$0.75) and china

(US$0.48).

Web Processing of Cotton:

Cotton

fibers are used in the manufacture of nonwovens either alone or in a blend. The

various processes for the manufacture of non-wovens are:

Hydroentanglement:

This

method of bonding provides strength to the Nonwovens, comparable to woven

fabric of the same basis weight. This method yields high strength without

interfering with the absorbency, tensile strength and aesthetic properties of

cotton. This type of nonwovens can be wet processed like the conventional woven

textiles for bleaching, dyeing and finishing. To manufacture soft loose

nonwovens, partially entangled webs are produced by subjecting cotton webs to

low water jet pressures (approx. 300-500 psi). These types of webs can be wet

processed in a pad/batch state. The limitations of this process are that

production has been limited to fiber blends because of problems in recycling

water and the quality of bleached cotton.

Needle

punching:

Needle

punched cotton provides highly efficient filter media based on the irregular

fiber shape and absorption properties. Increased tenacity in the wet condition

can be an important advantage for cotton filters. To build strength, scrim

materials can be used as in bed blankets and industrial fabrics. Needles of

36-42 gauges have been found appropriate for the production of cotton needle

punched nonwovens. For very heavy fabrics, use is made of gauge 32 and for

finer fabrics 40-42 gauge needles are being used.

Thermal

Bonding:

In this

process cotton webs with blends of thermoplastic fibers are passed between 2

hot rollers (Calendar rollers). The thermoplastic fiber softens/melts and bonds

the web. The initial work was done with polyester as the thermoplastic fiber.

Later polypropylene was extended for the study because of economics, density

and melting temperature considerations. This was mainly to study the

application as a diaper lining material. Substantial work is still being done

to develop this type of nonwovens.

Other

Bonding Systems:

Impregnating

the web with a resin or other adhesive material.

Stripping

off of the web with adhesive, which bonds the fibers together at regular

intervals.

Stitch

bonding: cotton web is stitched like in sewing and the product performance

depends on web weight, stitch/inch and type of sewing thread.

Application of cotton in Non-wovens:

Cotton

nonwovens are used as swabs, puffs, wipes, filters, weddings, personal care

products like in diapers & feminine hygiene products, semi-durable segments

like bedding, household furnishing, pillow fillers, etc.

Recent Reserch:

New

instrumentation to measure cotton contamination.

Cotton

linters to replace the traditional 100% wood pulp fibers for producing

absorbent cores for disposable diapers and famine pads.

New

quality measurements of small sample cotton are being developed.

Cotton

is being blended with kenaf fibers to improve the softness and hand.

Buckeye

Technologies has developed 100% natural cotton for tampon manufacture.

Clustering

analysis is developed for cotton trash classification.

New

method to improve the dyeability of cotton with reactive dyes.

Recent Development of Cotton:

Colored

Cotton:

Cotton

fiber is dyed with chemical dyes in order to get wide range of colors. These

chemical dyes and their finishing demands large amount of water in turn when

these water is disposed they cause soil and water pollution. Many dyes are of

chemical origin; particularly the azure ones and these are not environment

friendly. Hence many countries, including India, have prohibited use of

these dyes.

The

negative effects of dyeing can be reduced by naturally colored cotton. This

colored cotton is developed by gene transplantation. Crossing the genes

from wild cotton varieties with the cultivated white ones develops this colored

cotton. The research is being conducted at The University of Agricultural

Sciences (UAS), Dharwad Karnataka India, to promote the cultivation of

natural colored cotton. The colors that have been developed are

White, Orange, Red, Yellow, Green, Purple, Brown, Blue, And Black. These

negative effects of dyeing can be avoided by extensive research and growth of

colored cotton.

BT

Cotton:

Cotton

requires severe pesticide in order to combat numerous pests after some years of

use of pesticide by farmers these pests develop resistance to Particular

pesticide. This resistance force farmers to use more amounts of pesticides. BT

Cotton is developed by transgenic technique of implanting Bacillus Thuringiens

bacterial gene in to cottonseeds, which makes the cotton plant and seeds

resistant to majority of pests including bollworm(A. Lepidoptera), Tobacco

budworm (Heliothis virescens). Bt cotton is now one of the most widely used

transgenic crops. It is currently grown throughout the United States. More

than 2 million acres of Bt cotton are grown in the United States alone.

Other countries include China, India, and Australia. According to Dept. of

Agricultural and Resource Economics, University of Arizona. Bt cotton

planted from 1996 to 1998 is estimated to have yielded 5% more on average than

if traditional and decreased the quantity of foliar spray.

Cotton’s

Future Trends:

The

world's cotton fiber production is approximately 89 million bales [6]. In 1997,

a production forecast [6] shows that the U.S. is the largest cotton producer

(18.4 million bales), followed by China (17.5 million bales), India (12.8

million bales), Pakistan (8.0 million bales) and the former U. S. S. R.

republics (7.7 million bales). Other important cotton producers are Australia,

Egypt, Turkey, Brazil, Argentina, Paraguay, Greece and Mexico. The highest

cotton consumption is attributed to China (21.2 million bales), India (12.9

million bales) and U.S. (11.3 million bales).

Supplies: The world production will

increase a little bit. The 1998 U.S cotton crop is best described as a disaster

due to cool wet spring in the west and inadequate rainfall in the southeast.

Consumption: World cotton

consumption is lagging a bit behind production. After a surge in the mid-1980s,

world cotton consumption has been rather flat. But the long term potential for

cotton demand remains large.

All

cotton plantings for 1999 are expected to total 14.6 million acres, 9 percent

above 1998, and 5 percent greater than 1997. Upland cotton is expected to total

14.2 million acres, up 9 percent from last year. Growers planted 318,200 acres

of American-Pima cotton. This is a 3% decrease from last year's number, but 27%

higher than the acreage of 2 years ago. Planting in Georgia started extremely

slow due to a severely dry spring, but by June 1 was nearly on pace with

average. Conversely, Texas experienced a near normal planting season although

some replanting was necessary due to wind and hail damage.

Graph of World cotton area/World cotton

yields/World cotton production/World cotton consumption Graph of Cotton Prices

Conclution:

Cotton

nonwovens can be recycled, re-used or disposed off by natural degradation

conditions. Cotton is a readily renewable resource with long-term supply

assurance. Extensive research works is improving bleached fiber quality and

quantity. Nonwoven industries are producing various types of nonwovens with

different manufacturing techniques, for better production. Cotton share of the

textile fiber market has been steadily increasing and will continue to increase

as cotton-containing items is preferred by the consumers.

1 comment:

Very good information compile.d

Post a Comment